Concrete Batching Productivity & Control

Call us: +45 97 17 70 66

Stop Losing Money

Concrete Batching Plant Productivity – How much profit is being eaten away by waste and poor control in your concrete business?

Concrete production is complex and has a lot of variables. It’s not made easier when the industry struggles to retain a skilled labour force.

Losses of €200,000 are common.

Leakage comes from:

- Material Costs

- Batching Productivity

How can you reduce your waste to zero?

Read the article below and see if this problem is an issue in your business.

Concrete Batching Plant Productivity – Material Costs

If your concrete production is still using manual, semi-manual methods of the production process, then you could be bleeding profits.

50-70% of concrete production costs are raw materials. Poor use of these materials can reduce your margin.

Poor manual or semi-manual batching and a lack of confidence in your batching process forces many manufacturers to overdesign to ensure product quality.

A 50,000m3 operation over batching by just 1% is giving away 500 m3 of concrete. With a sales cost of €100, that’s €50,000 of lost revenue for a 1% over batching error.

If you produced say just a 3% of low-quality concrete that was rejected by your customer. You had no proof of the batch details this 1,500 m3 of waste concrete. The loss in revenue is €150,000 + the cost of disposal €50,000 = €200,000 for a 50,000 m3 operation.

Concrete Batching Plant Productivity

Understanding the batching process and cycle times of batching is profit critical.

The batching cycle and timing are profit critical. The more batches you can get in an hour the more concrete you can sell. There are many variables to the batching cycle and we have written a separate article to cover productive batching cycles.

If there is an issue with the batching plant it is import to know and adjust the process or have a quick shut down to replace a spare part.

Failure to do this will result in poor concrete and rejected loads with a loss as described above.

Plant stoppage due to poor stock control will reduce productivity another waste that requires management control.

A one-day unscheduled shutdown on a 50,000 m3 plant is a loss of revenue of €25,000.

Stop Profit Leakage with Concrete Batching Control

CEO

Imagine being the CEO of a concrete company and you have an app on your phone where you can log into any batching plant you own and see real-time production data.

How many M3 on concrete has the plant has produced today, yesterday, last week, last month, last year?

Production Manager

How much stock is in the storage bays?

What is the productivity of each plant?

Plant Operator

Which part of the batching process is live, what is the next process?

Are any of the motors overheating, suggesting a planned shutdown?

We Have The Technology

The technology is already built into our batching plant. Our mission is to help you make more profit and reduce your waste.

Complete the form to get a price

Request a Price

Have You Read Our E-Book?

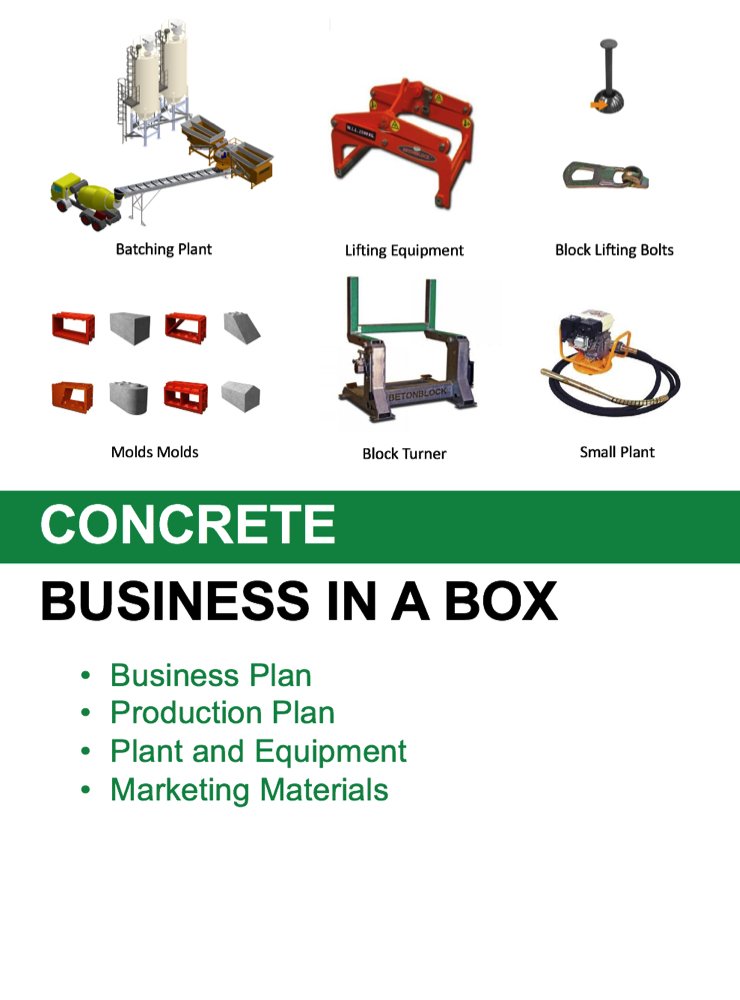

We have put together several concrete business ideas that will help you build a concrete business.

The more concrete you can sell the more money you will make. The first part of the business plan is the business case to purchase the batching plant and twenty steel block moulds to make concrete blocks you can sell.

The business case is a starter pack that will produce 400 m3 of concrete per month. When you add more business ideas as our plan, the business opportunity becomes very profitable.

Marketing and generating leads is the art of making money. We have also provided you with marketing ideas and materials, that can be branded to suit your business.

Select The Batching Plant For Your Project

Let’s find your solution

Call us: +45 97 17 70 66