Recycled Concrete

Call us: +45 97 17 70 66

Recycled Concrete Demolition Site Case Study

A good example for a recycled concrete case study is Kings Crescent Estate, Hackney.

The London Borough of Hackney Council regenerated of a number of estates. The housing stock was upgraded to the decent homes programme in the London area.

The Kings Crescent Estate was reported to have been poorly designed and did not meet the decent homes standard.

The estate comprised of five, six and seven-story housing blocks around the perimeter and a number of two-storey dwellings in the centre.

The accommodation was a mix of low rise housing with one and two bedroom flats, and three and four bedroom maisonettes.

There were several sealed-off semi-submerged underground car parks.

Recycled Concrete Pre-Demolition Audit

A pre-demolition audit was carried out to determine the quantities of materials for recycling and landfill disposal. The results of the pre-demolition audit are in the table on the left.

The pre-demolition audit allowed the contractors tending for the project to work out the best and most economical methods for recycling and to offer the client the best value for the project.

The demolition of the buildings was carried out by soft stripping, using the traditional removal of all hazardous materials first followed by the structural demolition of the buildings using low-rise machines with demolition attachments such as breakers and hammers.

Recycled Concrete Building Types

The table on the right shows the recycled concrete demolition materials from a number of building types.

The information came from pre-demolition audits and shows the importance of carrying out the audits.

Contractors can determine the best way to recycle the demolished material.

The material we are interested in is concrete. Crushed concrete can be used for fill or to make concrete.

The most profitable option is making concrete. See our article on recycled aggregate as we show an example of the cost to produce aggregate for new concrete using crushed concrete. Click on the link for more information on concrete recycling production.

Have You Read Our E-Book?

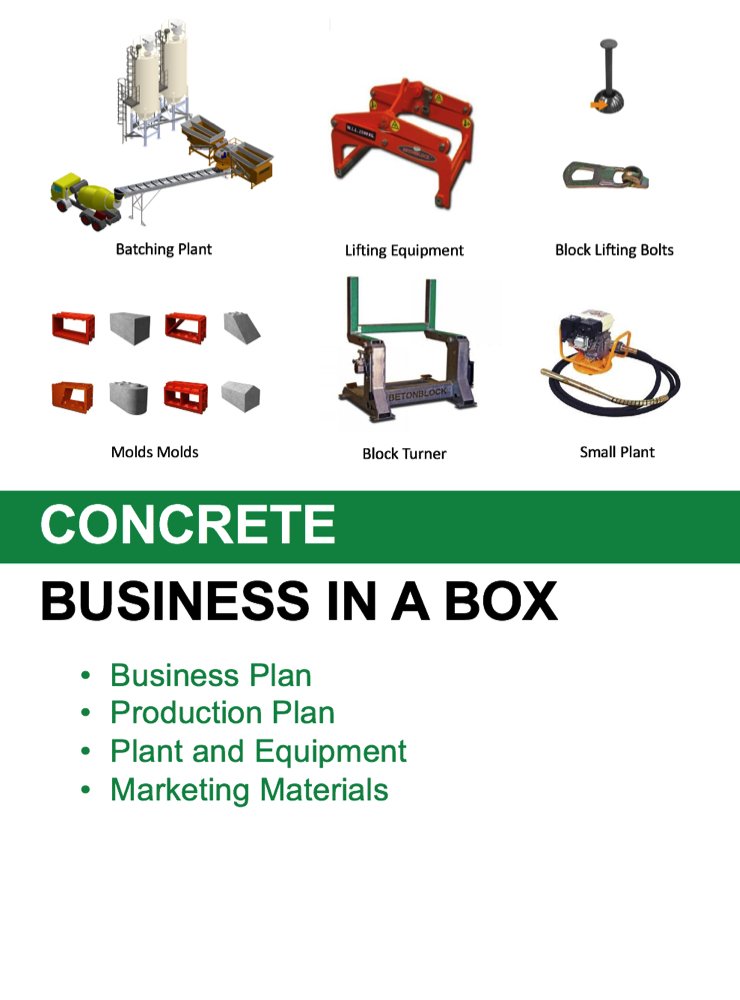

We have put together several concrete business ideas that will help you build a concrete business.

The more concrete you can sell the more money you will make. The first part of the business plan is the business case to purchase the batching plant and twenty steel block moulds to make concrete blocks you can sell.

The business case is a starter pack that will produce 400 m3 of concrete per month. When you add more business ideas as our plan, the business opportunity becomes very profitable.

Marketing and generating leads is the art of making money. We have also provided you with marketing ideas and materials, that can be branded to suit your business.

Select The Batching Plant For Your Project

Let’s find your solution

Call us: +45 97 17 70 66