Soil Stabilisation

Call us: +45 97 17 70 66

Soil Stabilisation

Soil Stabilisation is a method to strengthen soil when the ground bearing capacity of the ground is poor and too weak. Soil stabilisation is used for the construction of foundations, buildings, roads, railways, airports and the like.

Stabilisation Soil Types

The soil types for treatment can be almost any combination of sand, gravel, silt, crushed stone, natural gravels. Waste material can also be used such as cinder, fly ash, foundry sands and screenings from quarries and gravel pits. Old road granular base with or without bituminous coatings is another source of suitable material for treatment.

Cost-Benefit of Soil Stabilisation

When the ground conditions are not suitable for construction, the client has four options:

1. Find a new construction site

2. Redesign the structure for poor soil.

3. Remove the poor soil and replace it with good soil.

4. Improve the engineering properties of the site soils.

Option four can be an economical solution for some sites.

Soil Stabilisation Advantages

- Waterproofs the soil

- Improves soil strength

- Reduces soil volume change due to temperature or moisture

- Improves soil workability

- Reduces dust in the work environment

- Upgrades marginal materials

- Improves durability

- Dries wet soils

- Conserves aggregate materials

- Reduces cost

- Saves energy

- Reduces pavement thickness

- Improves stiffness and tensile strength of the material

Environmental Benefits of Soil Stabilisation

- Life of landfill extended

- Natural resources are extended

- Emissions from transport reduced

- Transport miles reduced

Soil Stabilisation Methods

There are many ways to stabilise soil. Before a method is selected test the soil in a laboratory. Tests can then be carried out using the various techniques to ensure the design strength of the sub-base can be achieved. The method selected will be determined by the economics of the technique to make the design strength.

- Cement Stabilisation

- Lime-Pozzolana Stabilisation

- Soil-Bituminous Stabilisation

- Organic Stabilisers

Soil Stabilisation Costs

Soil stabilisation is very economical when comparing it with imported granular fill and many piling options.

For example, when being used for equal load-bearing capacity for pavement and road construction, soil treatment is a more competitive solution.

The economy is achieved by using existing soils rather than importing new materials. No costly haulage and imported granular sub-base are required, saving both energy and raw material.

Soil Stabilisation for Road Construction

One of the most significant usages for soil stabilisation is pavement/road construction. Usage includes the construction of highways, major roads, streets, parking areas, industrial storage facilities and airports.

There are three main components of soil-cement pavement products, they are:

Full-Depth Reclamation

The old road surface of asphalt and the sub-base is recycled to create a much stronger aggregate cement sub-base for the new road.

Cement-Treated Base

Soil and or granular soils mixed with cement and water. The material hardens after compaction to create a durable paving material.

Cement-Modified Soils

Mix a small amount of cement with the poor soil to enhances the properties of the sub-base for road construction.

Soil Stabilisation Case Study – Bovanenkovo Airport

Location: North-East part of Yamal Penninsula, 40 km from the Karskoe sea coast near Bovanenkovo settlement.

Plant Used: FIBO INTERCON Soil Mixing plants models F1800 and

F2200

At Bovanenkovo Airport the ground is made up of permafrost soils and aggregates. The ground bearing capacity was too weak for construction of the buildings and runways. The spoils and aggregates required stabilisation to strengthen the soil properties and improve the ground bearing capacity.

Soil and aggregates were excavated and mixed with cement and a chemical additive to reduce the water content within the soil. Soil was then returned to the foundation and compacted. The result was a foundation sub-base that now had functional bearing capacity to construct the airport buildings and runways.

Construction of the airport was carried out in three phases: the helicopter airport, winter runway and the concrete runway together with the air terminal for passengers.

Soil Stabilisation Plant Used at Bovanenkovo Airport

A Bovanenkovo Airport the contractor purchased an F2200 batching plant to carry out the soil mixing and then to make concrete for the construction of Bovanenkovo Airport. The plant in the images on the left is the actual plant.

The F2200 can produce about 100 m3 of soil cement mix per hour. And between 10 to 45 m3 of concrete per hour.

Production can be doubled up using two machines.

The plant is semi-mobile and can be offloaded and set up on flat ground ready for production within a few hours. The following case study gives an example of how the F2200 can operate.

Have You Read Our E-Book?

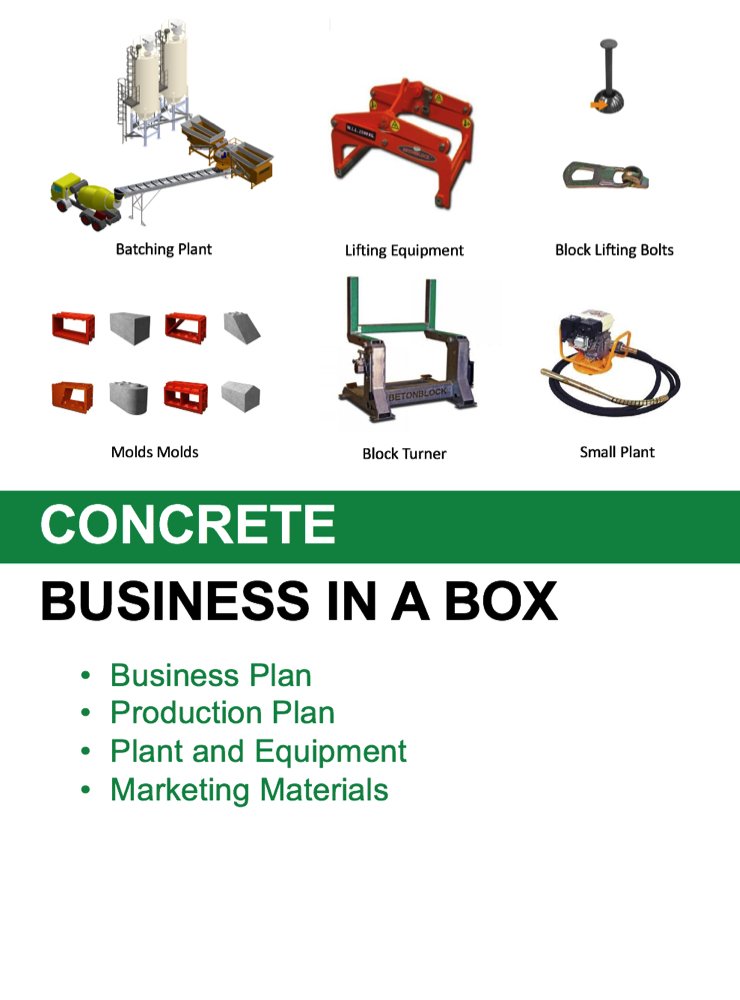

We have put together several concrete business ideas that will help you build a concrete business.

The more concrete you can sell the more money you will make. The first part of the business plan is the business case to purchase the batching plant and twenty steel block moulds to make concrete blocks you can sell.

The business case is a starter pack that will produce 400 m3 of concrete per month. When you add more business ideas as our plan, the business opportunity becomes very profitable.

Marketing and generating leads is the art of making money. We have also provided you with marketing ideas and materials, that can be branded to suit your business.

Select The Batching Plant For Your Project

Let’s find your solution

Call us: +45 97 17 70 66