Mining Engineering

Learn about mining engineering, tunnelling and concrete

Finance your project

Mining Engineering

Mining Engineering and Tunnel Engineering

This article introduces mine and tunnel engineering and is a useful read for young engineers and people wishing to understand the mine and tunnelling sector.

Mining is the extraction of minerals from below and above the ground.

Tunnels are underground passages used for transportation.

There are many different methods to construct transport and mine tunnels. You can read about more techniques on the tunnel engineering page. The example below gives you an idea of what is involved in building a tunnel through hard rock.

The New Austrian Tunnelling Process

The new Austrian tunnelling process was developed in the nineteen sixties by an Austrian engineer. The method uses a standard process designed to optimise the tunnelling process. The method uses modern monitoring techniques to optimise rock reinforcement methods. The video above shows the process described below.

Step 1 – From the last blast and de-gas, clear away the spoil and rock from the rock face.

Step 2 – Scale the tunnel surfaces to remove all loose rock with a chiselling tool to give a final shape to the tunnel. Scale the surface with high-pressure water to remove small loose rock and dust in preparation for the shotcrete.

Step 3 – Apply the shotcrete to the surface of the rock to bond it together.

Step 4 – Drill and fit steel rock anchors. These usually are 2m to 6m long.

Step 5 – Drill the rock face and place explosives for the next blast.

Step 6 – Blast and de-gas. The explosion breaks up the next section of rock. The explosion causes dust and gas that needs to be removed from the environment using a powerful air extraction system to keep the tunnel safe.

Step 7 – Repeat the process.

Mining Equipment

There is a large range of mining and tunnelling equipment on the market. The type of plant and equipment depends if the mining work is above or below ground.

Above ground, the plant and equipment are mostly excavators and trucks.

The equipment type below ground depends on the material the tunnels are being excavated through, for example, soft rock or hard rock. There are many methods, and each one uses different equipment.

Learn more about mining equipment types

Mining Equipment Manufacturers in World

The global mining plant and equipment market is expected to grow by 5.46% from 2018 to 2024. Value of the market is expected to be $112 billion by 2026 from $76 billion in 2018.

The underground mining plant and equipment market is expected to grow by 6.5% from 2020 to 2020. The market’s value is expected to be $26,270 million by 2025 from £20,420 million in 2019.

Below you will find a link to the world’s top mining equipment manufacturers.

List of Mining Equipment Manufacturers.

Tunnel Engineering

Constructing tunnels is a specialist civil engineering discipline. There are many ways to build a tunnel. The method will be determined by the type of sub-strata the tunnel will pass through. The different types of tunnel construction include:

- Boring tunnels using TBM machines(Tunnel boring machines)

- Sprayed concrete lining tunnels

- Tunnels constructed by blasting with explosives

- Pipejacking

- Pipe ramming

- Trust boring

A large number of tunnelling techniques required many specialist skills, knowledge and specialised plant and equipment.

The selected construction method will depend on the tunnel’s length and size and the ground and groundwater conditions.

Learn more about Tunnel engineering

Tunnel Linings

There are two core purposes for a tunnel lining. The structural support of the exposed strata the tunnel passes through maintaining the tunnel’s cross-section and provides a barrier to stop water ingress into the tunnel.

To provide an internal surface for the operational use of the tunnel.

Learn more about Tunnel linings

Rock Reinforcement

Rock reinforcement within the mining and tunnel engineering sector is all about rock bolts and anchors. The range of bolt types and the machinery required is fascinating.

Learn more about Rock reinforcement

Shotcrete and Gunite Sprayed Concrete

Shotcrete and Gunite are names for sprayed concrete.

Gunite was developed in 1895. Gunite uses a dry mix concrete pumped to the nozzle with compressed air and water added at the nozzle.

Shotcrete was developed just after world war two. Shotcrete is a premixed wet concrete that is pumped to the spray nozzle by compressed air.

With the use of innovative chemical additives, both types of sprayed concrete are very popular.

Sprayed Concrete Lining

The sprayed concrete lining method of tunnel construction is very common. The tunnel is excavated, and a concrete lining is sprayed against the earth or rock to provide temporary and permanent support.

Some tunnels are constructed by using a temporary sprayed lining, and then a second precast concrete segmented lining is put in place for the permanent solution.

Learn more about sprayed concrete linings

Waterproofing Engineering

Waterproofing mines can be a challenge. Tunnels close to the surface usually are constructed using a cut and cover method and waterproofed quite easily.

Deep underground tunnels are more challenging. The water pressure at depth and the options available mean the work has to be well planned.

Most bored tunnels are below 50 metres, and at these depths are constructed through some form of rock.

Waterproofing Methods

Four main waterproofing methods can be used. They are:

- Crystalline Systems

- Membrane Systems

- Drainage and Water Stops

- Polyurethane Grout Systems

- Learn more about waterproofing in mine construction

Mining Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

The mixing plant is controlled by a state of the art software that ensures concrete quality and efficiency in delivering outstanding productivity.

Learn more about Fibo Intercon shotcrete and grout mixing plant.

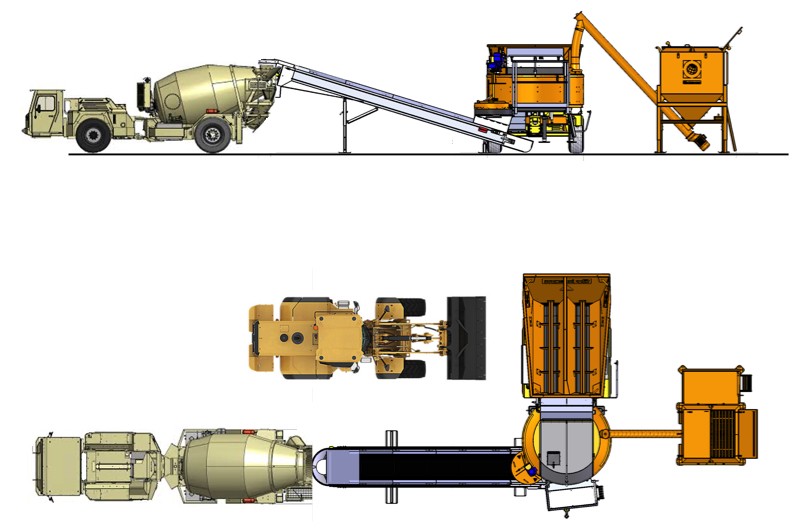

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.