Mining Equipment

Learn about mining equipment, tunnelling and concrete

Finance your project

Mining Equipment

Types of Mining Equipment

There is a large range of mining equipment on the market. The type of plant and equipment depends if the mining work is above or below ground.

Above ground, the plant and equipment are mostly excavators and trucks.

The equipment type below ground depends on the material the tunnels are being excavated through, for example, soft rock or hard rock. There are many methods, and each one uses different equipment.

List of standard mining equipment:

- Rock scaling equipment both mechanical and hydro

- Man lifting equipment

- Loader plant to move materials

- Concrete batching plant

- Shotcrete mixing equipment

- Shotcrete spraying equipment

- Water jetting equipment

- Explosive and bolt drilling plant

- Explosives Charging Equipment

- Cement silos

- Rock hauling plant, and concrete transport equipment

Most Used Types of Mining Equipment

If you are new to the mining industry and wish to learn about the most common mining equipment types, we have given you some insight below.

Mining Drilling

Drilling plant and equipment is one of the most used pieces of equipment used in mines to drill bold holes for rock reinforcement and drill holes for explosives.

The drilling machines are mostly robotic, as they are very efficient.

Transport Plant

There is always a lot of material to be moved around within a mine and tunnel. Loaders, trucks, rail, skips, lifts and elevators are used to move materials from one location to another.

Concrete Plant

The lining of the tunnel or mine is usually an application of shotcrete. Shotcrete is sprayed on concrete. The concrete materials of sand, aggregate, cement, water and chemicals are mixed in a shotcrete smart mixer. The batched concrete is then put in the spray machine hopper. The spray machine is usually robotic and uses compressed air to spray the concrete onto the tunnel’s sides or mine.

Scaling Mining Equipment

Before shotcrete can be applied to the tunnel or mine sides, the rock surface needs to be scaled. Scaling removes loose rock and gives a final shape to the tunnel/mine. Two scaling techniques are used; the first one uses a mechanical chiel to remove the loose rock and shape the walls’ sides. The second technique uses high-pressure water to remove smaller loose rock from the mechanical scaling and remove dust.

Mining Equipment Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

The mixing plant is controlled by a state of the art software that ensures concrete quality and efficiency in delivering outstanding productivity.

Learn more about Fibo Intercon shotcrete and grout mixing plant.

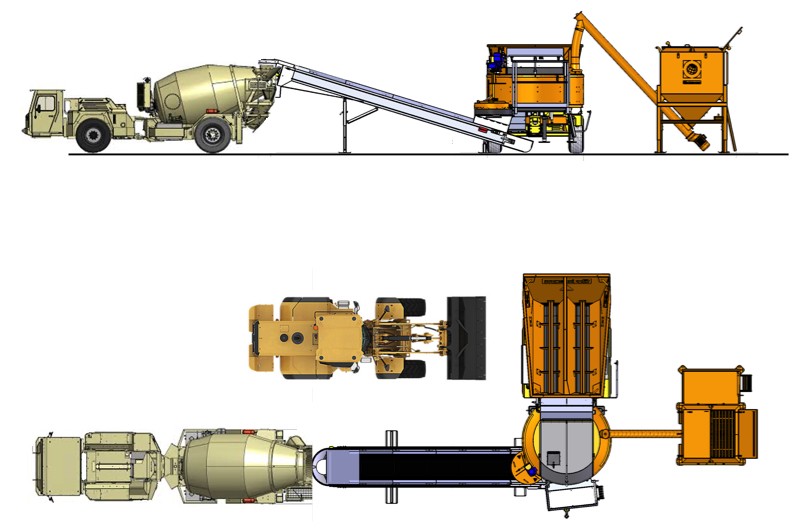

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.