Concrete Testing Laboratory

The concrete testing lab gives you, your own on-site testing facility for efficiency and control.

Concrete Testing Laboratory

On-Site Concrete Testing

From time to time, our customers require an on-site facility to test concrete.

The Fibo Intercon concrete testing laboratory container is designed for use on remote sites, enabling the routine testing of concrete and soil to the requirements of the technical specifications and standard codes.

The concrete laboratory container comes with a standard set of concrete testing equipment listed below. The equipment list can be adjusted to your requirements.

Testing Lab Technical Specifications

The concrete testing lab container is available in various dimensions depending on use and space required for the particular project.

The standard concrete testing laboratory is equipped with: tables, sink, cupboards, drawers, shelves, electrical installations, including power sockets, light and air conditioning/heater to maintain the correct testing temperature in the container.

Concrete Testing Lab Options

The standard laboratory is constructed on a steel frame with corner casts and forklift pockets for easy transport and moving from location to location.

The laboratory design allows the routine testing of concrete and soil.

Concrete testing ensures the concrete you are producing on-site is in-accordance with the design specifications for the project.

Testing the concrete and keeping records of the tests gives you a fully traceable and compliant quality assurance process and system.Our Concrete Laboratory Container is easy to set up.

Our in-house engineers can give you a full concrete testing service, including:

- Concrete mix design

- Concrete testing training

- Concrete quality assurance processes and systems

- Concrete quality assurance training

Get a Price For a Concrete Testing Laboratory

Recommended equipment

The testing of fresh, hardened and in-situ concrete is vital to ensure that concrete structures comply with specifications and relevant standards.

We have put together the essential equipment to carry out standard concrete testing.

To perform the different tests on building materials such as aggregates, cement, soil, and asphalt, an extensive range of laboratory equipment is required. We can equip the laboratory with alternative equipment on request.

Concrete Testing Equipment

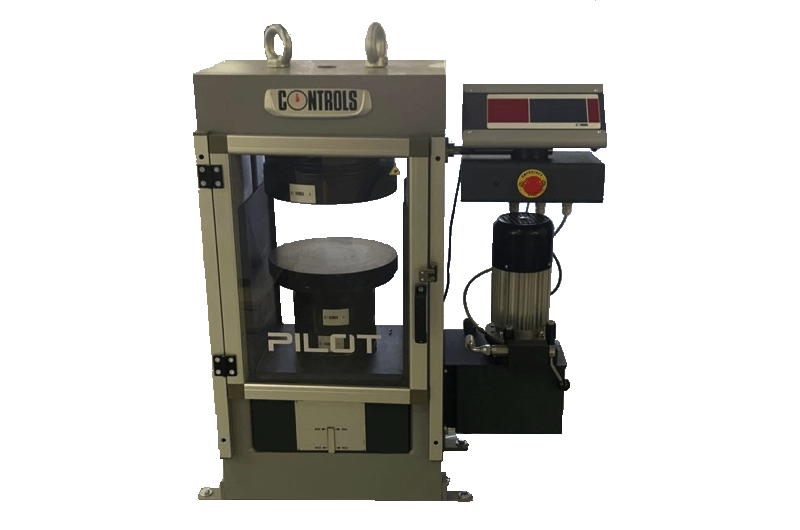

Automatic Compression Tester

This automatic compression tester for cubes, cylinders and blocks, combine high productivity with Energy Saving. The compression tester is an advanced model giving excellent results.

Curring Tank

The curing tank comes with a drain cock, digital heating system, and a robust metal internal base to hold the concrete test cubes.

Vibrating Table

The vibrating table is robustly manufactured to operate with the minimum noise level. The operational output is3000 vibrations per minute (3600 at 60 Hz).

Laboratory Oven

Forced convector laboratory oven with a digital thermo regulator designed for drying asphalt, soil, rock, concrete, aggregate or similar materials.

Electromagnetic Sieve Shaker

The vertical sieving motion is provided by an electromagnetic unit, to obtain the best results for sand and aggregate analysis. The shaker can be supplied with noise reduction cabinet and a wet sieving attachment.

Testing Sieves

We offer a complete range of full depth testing sieves 200, 250, 300 and 450 mm dia.

Slump Cone Test Set

A portable slump cone test including steel cone, metal base plate, graduated tamping rod and scoop.

Air Entrainment Meter

The air content is an essential parameter for the behaviour of concrete to weathering and to verify the air content variation due to the use of chemical additives to increase the workability of concrete.

Cube Moulds

Ideal and very practical for field use and production control.

The testing cubes are made from steel for long life.

We supply 4 number 150 x 150 x 150mm cubes with our standard set up.