fibo Collect

L-shape Model

Call us: +45 97 17 70 66

Introducing the L-shape layout

fibo Collect is an innovative touchscreen solution designed specifically for the collection of concrete, mortar, screed, and loose aggregates.

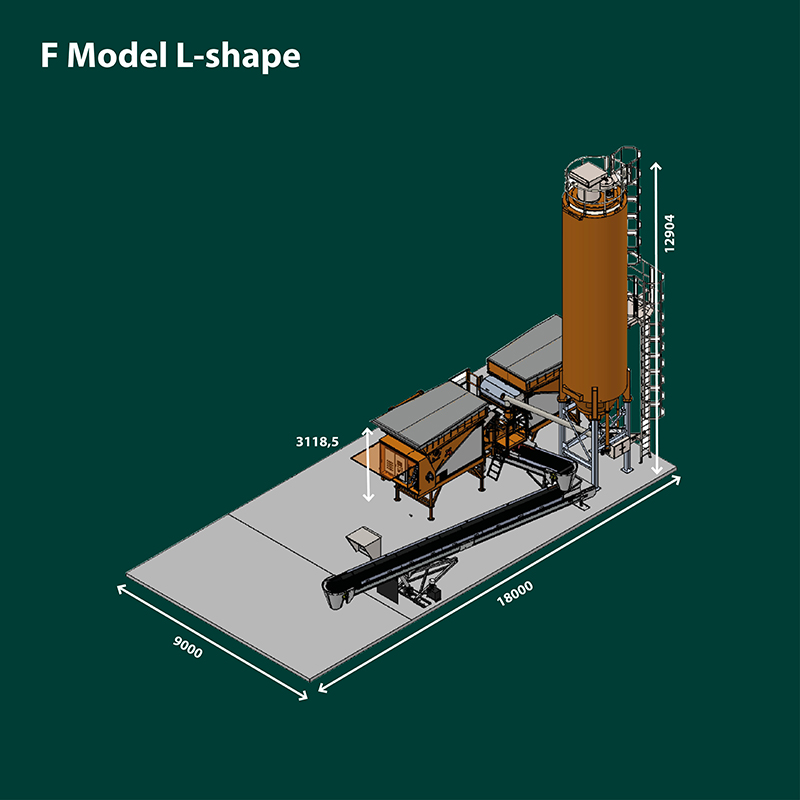

At fibo Intercon, we understand that space is a crucial factor, especially when it comes to merchant and retail environments. That’s why our expert engineering team has been working tirelessly to develop new ways to enhance the efficiency of our system, while also reducing the space requirements. And now, with the introduction of our L-Shape configuration, we are proud to offer a more compact design that provides all the functionalities of the full F1200 solution including the ability to collect concrete, mortar and screed.

Space requirements

One of the most frequently asked questions is, “How much space is required?”. With the new L-shaped layout, we can comfortably fit the entire F1200 solution, which includes 4 aggregate hoppers suitable for concrete mortar and screed, into a 13 x 9m footprint. The maximum length is 18 m ensuring optimal utilization of available space without compromising functionality.

Cement silo options

Now, let’s address another common concern – the need for a large vertical silo. Here at fibo Intercon we believe in providing our customers with versatile options. Our range of cement silos includes the horizontal silo, the vertical silo, and the big bag silo.

The horizontal silo is perfect for those looking to reduce height while maintaining silo capacity. The vertical silo is the optimal solution for those looking for increased storage capacity but limited space on the ground. On the other hand, the big bag silo offers a convenient solution for customers aiming to minimize the size of their setup by using bulk bag cement. Whatever your specific requirements may be, we have the right option for you.

Loading aggregate hoppers

When it comes to loading the aggregate hoppers, our setup is optimized efficiently. Customers using the fibo Collect configuration are advised to load the hoppers from the opposite side to the conveyor belt and silo.

To further support our customers, fibo Intercon offers a range of technical add-ons to facilitate loading hoppers without any risk of contamination

Loose aggregate alternative

But what if you don’t have loose aggregates? We’ve got you covered with the latest addition to our product lineup – the ‘fibo Collect: bulk bag unloader’ system. This ingenious solution provides a safer and smarter method for discharging aggregates directly from a bulk bag into the aggregate hoppers. With our four pyramid-shaped blades mounted on top of the hopper, users can simply drop the bulk bags onto the blades. As the bag is lowered, it is cut in four directions, allowing the contents to discharge effortlessly into the hoppers. This eliminates the need for users to put any part of their body underneath the suspended bag during the unloading process, ensuring maximum safety and efficiency.

fibo Collect return on investment

Now, let’s address an important question on everyone’s mind – the cost of a fibo Collect unit. As each system is tailored to meet specific requirements, a bespoke design is often necessary. We understand that pricing is a vital aspect, and to provide you with the most accurate information, we kindly request a few details to be clarified before we can supply a price.

Get started by completing the ROI Calculation form

Conclusion

We are incredibly excited about the launch of our fibo Collect ‘L-Shape’ Model, which brings unprecedented convenience, efficiency, and space optimization to the world of small load collection. Whether you’re in the construction industry or a retail environment, our innovative solution is sure to revolutionize the way you sell concrete, mortar and screed. Contact our sales team today to discuss your specific requirements and discover how our cutting-edge F1200 ‘L-Shape’ Model can transform your operations.

Ready To Move On?

Let us bring you closer to becoming a sustainable construction company.