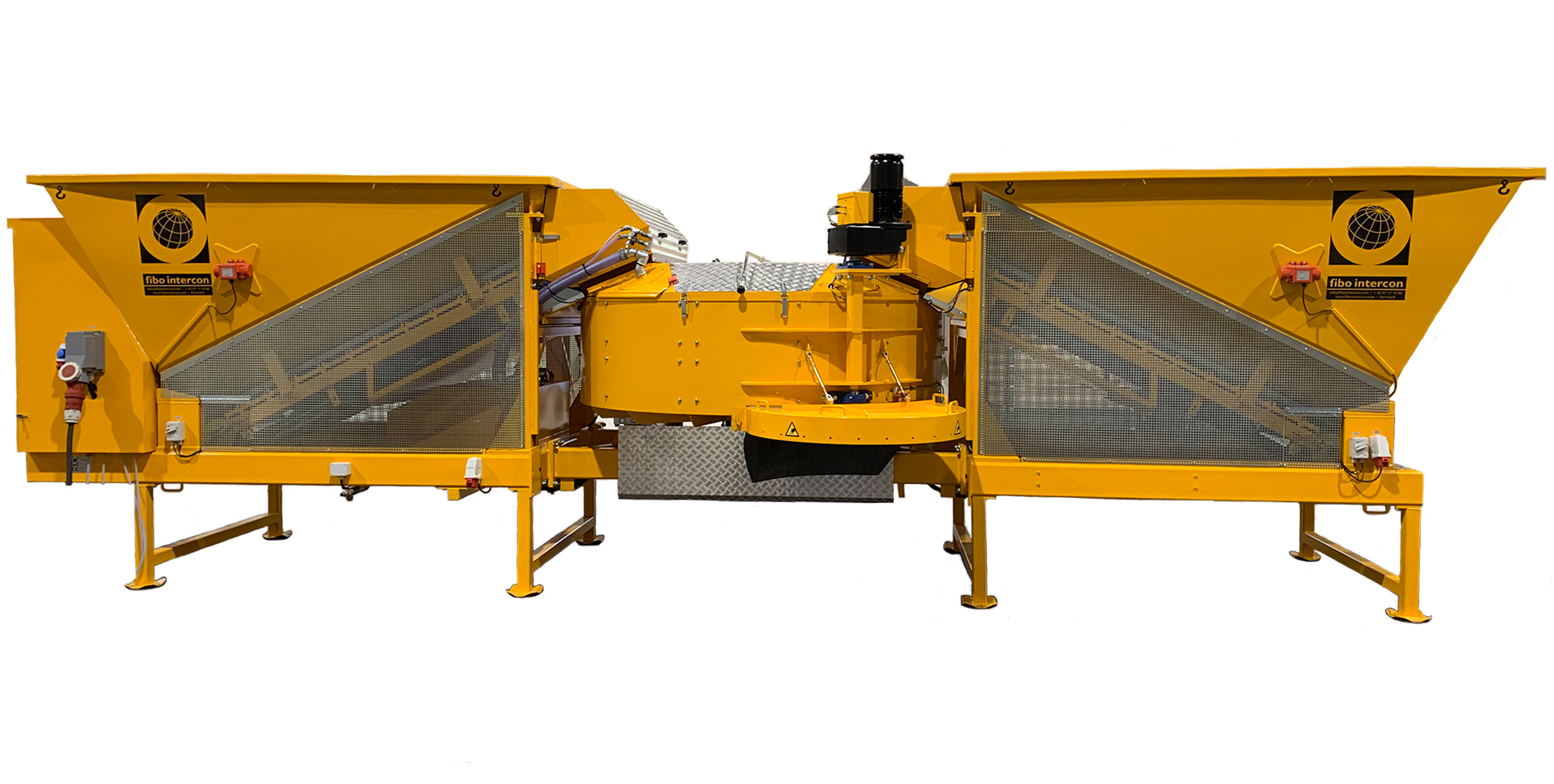

Concrete Batching Plant on legs, with 4 hoppers

F-model (10 – 45m³)

Need help? +45 97 17 16 66

Concrete batching plant on legs

Our F-model is a mobile concrete batching plant on legs, designed to offer the end user a very productive, reliable and cost-effective piece of equipment. It is the best choice for temporary site projects or stationary locations.

The difference between the F-model and the FS-model is the FS-model has two aggregate bins whereas the F-model has four. Both the F- and FS-model are mounted on legs.

For different expectations,

different solutions

In other words, Fibo Intercon batching plants are able to supply all expectations of customers.

Due to different types of concrete needs in different fields, Fibo Intercon has several options that are suitable for different concrete applications according to customers’ needs and technical requirements.

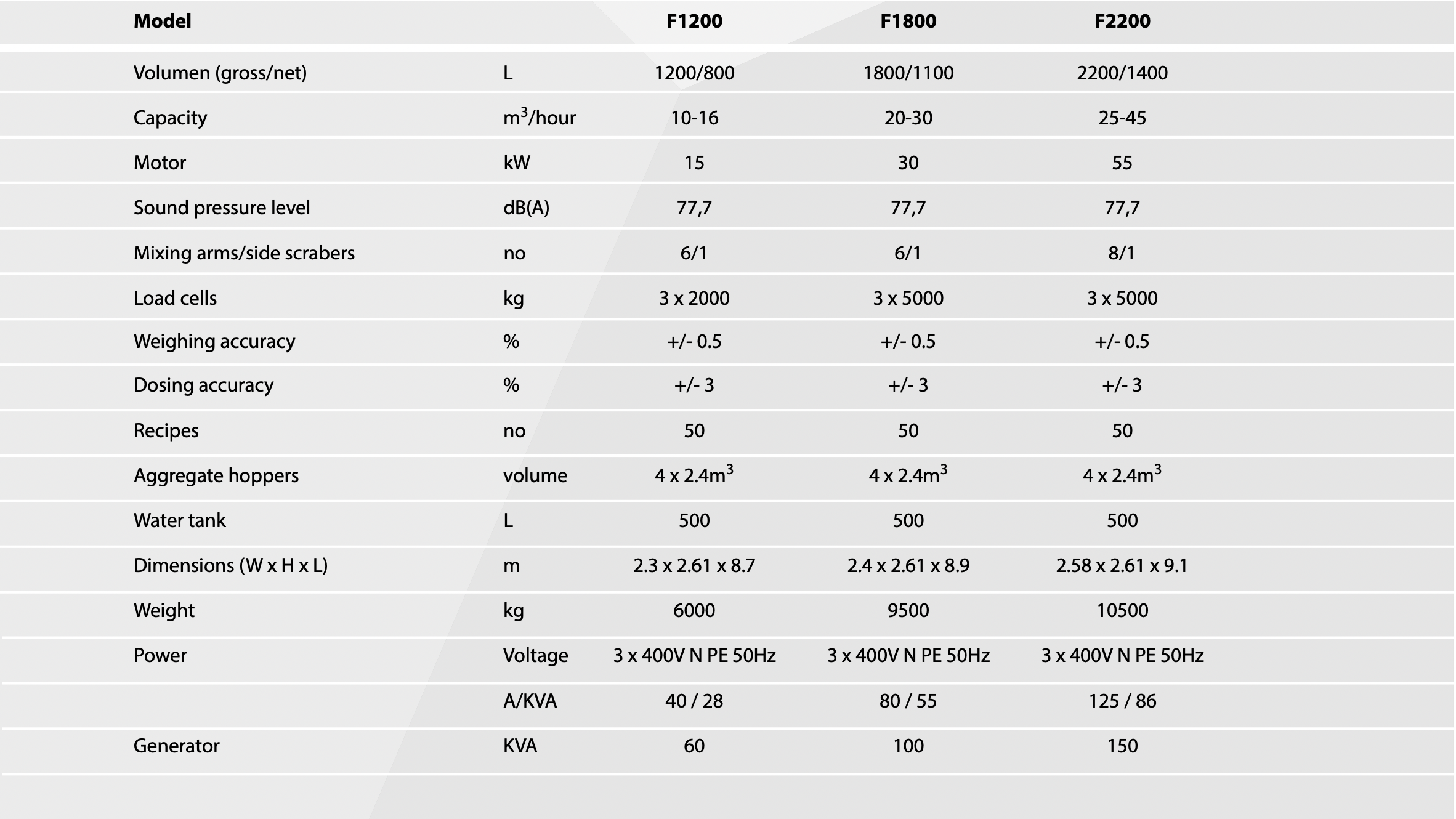

Technical specification F-models

Our product range of F-models is comprised of three types of different capacities 1200, 1800 and 2200 Liters.

The F-model is a mobile concrete batching plant on legs, with 4 hoppers. Built on a solid frame, with legs. The batching plant features different size mixers, very precise dosing, and many options to produce any kind of concrete required. As a result, Fibo Intercon mobile batching plant will precisely produce the required amount of concrete, without waste of time or materials.

Talk to a specialist about your challenges

Tell us about your challenges and our team of specialists will develop a solution specially tailored to your needs.

Let’s find the best solution for your project.

Let’s take your next steps together!

The design of your Fibo solution is often complex. Our technical sales team can support you in selecting a suitable layout and equipment to optimise your productivity and business.