Concrete Calculator

Use the concrete calculator to calculate concrete volumes, price, cost and the return on investment from the purchase of concrete batching plant.

Concrete Calculator

Please use this calculator to estimate the quantity of concrete required for your project.

Fibo Collect the NEW way to sell concrete

New Business Opportunity

Watch the video to see how a Fibo Collect batching plant can help you build a business and give you:

- New revenue streams

- New customers

- New products

- New services

- Develop your market share

Watch the video to learn more.

Concrete Calculator for Volume

On the second sheet of the spread sheet you will find the method to calculate:

- Cube – lxbxh

- Cuboid – lxbxh

- Cylinder – πr2h

- Sphere – 4/3πr3

- Cone – 1/3πr2h

Enter your dimensions and the calculator used the above formula to give you the results.

Concrete Cost Calculator

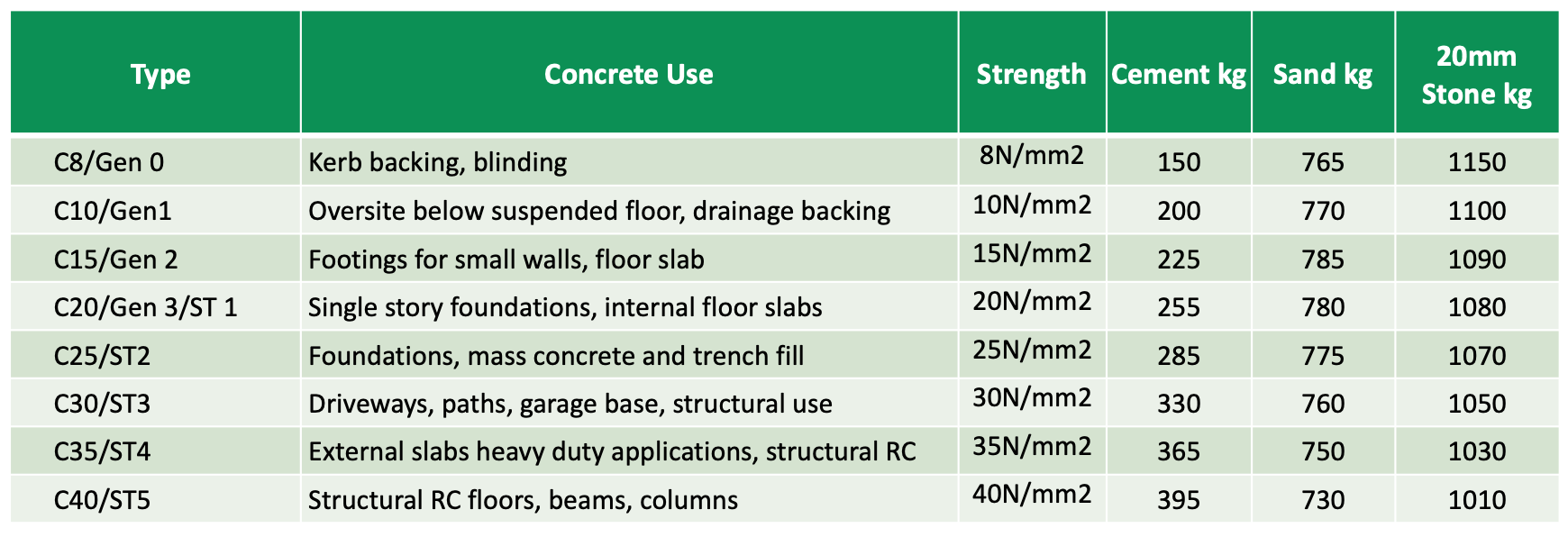

You can calculate the cost of C10, C15, C20, C25, C30, C35, C40 and other common mixes using the calculator. The calculator includes the mix proportions in tables.

Enter the mix proportions. In the example of the page we have calculated the cost of a C25 prescribed design mix. The proportions are 285kg cement, 775kg sand, 1070kg aggregate, 100 lites of water.

Enter the cost you buy the materials for and the calculator will give you the cost. We have added in the cost of the batching plant and the labour cost mixing the concrete. In our example the cost of the C25 concrete is €68.69 per m3

When comparing to buying ready-mix concrete there is a €21.31 saving. if you were buying 10,000 of concrete per year the saving would be €214,100 more than the cost of the batching plant.

You can download the calculator at the bottom of the page.

Concrete Calculator for The Return on Investment

You can use the same spread sheet to calculate the return on investment for the purchase of the batching plant. In the example we have included the cost of a B1800 concrete batching plant, with a big bag silo and cement auger and some additional extras. Total investment including finance costs is €147,195.

The volume of concrete the owner uses in the example is 14,000m3 per year. We have selected the B1800 because it is the ideal machine for this volume. The B1800 can produce 20/30 m3 of concrete per hour.An average of 25m3/hr is 200m3 per day and 40,000 m3 per year giving room for expansion.

As you can see at the bottom of the calculation the B1800 is paid back just under six months or after mixing 6,907 m3 of concrete.

Concrete Ratio V Prescribed Mixes Concrete Calculator

You will notice in the concrete calculator spread sheet there are two tables for concrete mixes. They are:

- Concrete Mix by Volume Ratio

- Prescribed Concrete Mixes

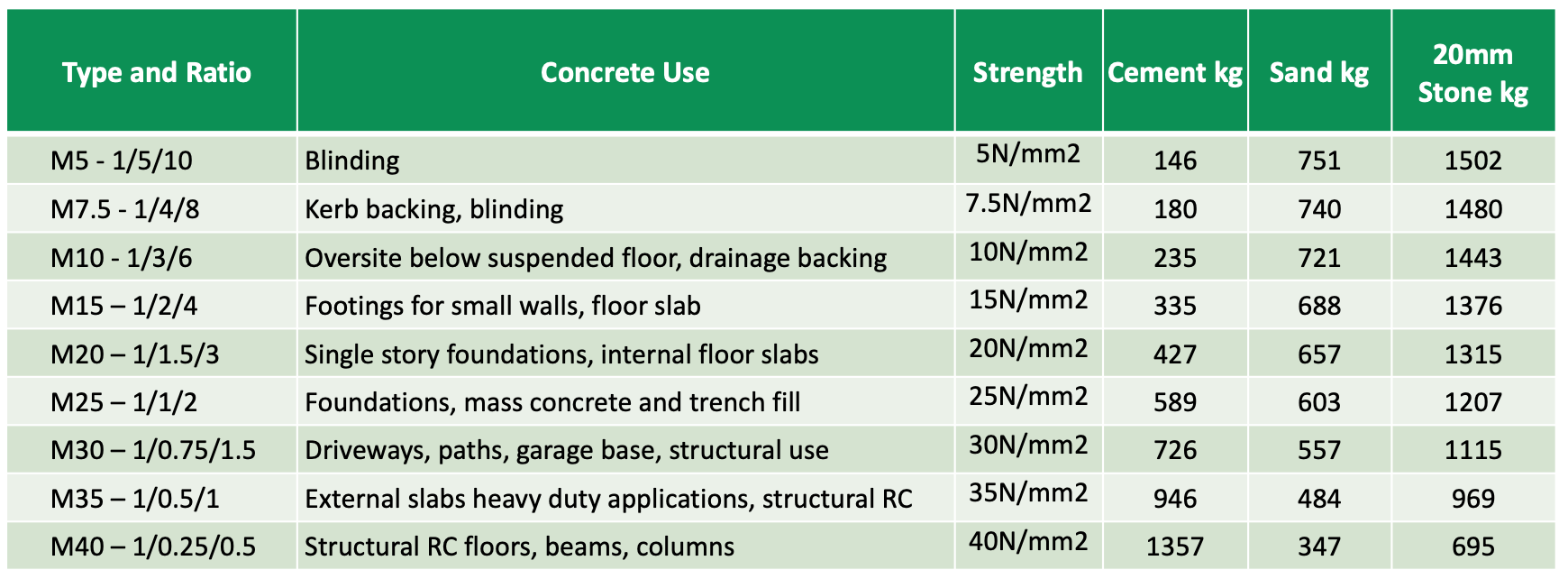

The concrete mix ratio table gives the mix proportions by volume parts then converts them into kg to mix 1m3 of concrete. You will notice when the concrete strength increases using this method. The cement content increases far more than the prescribed concrete mix table.

For example, the C30 mix includes 726kg of cement in the mix ratio table and only 330kg in the prescribed mix table. The cost difference will be significant if you run this through the calculator.

Table For Concrete Design by Volume Ratio

Use this table if you can only mix the concrete by volume. For example using a bucket. This method used more cement than the prescribed method and is for small batches of concrete.

In BS 8500 the minimum cement table gives you the minimum cement content for each mix. The table is for a slump class of S3 (mass fill foundations)

Concrete mix ratio by volume was developed as a guide but is not accurate. The two ways of looking at concrete mixes can be confusing if you are new to concrete mix design.

Using the prescribed concrete mix table is more accurate but is only a guide. To ensure the mix meets the design mix strength carry out trial mixes. If you need support with design mixes text 07896 246 224 and I will answer your questions.

Table for Prescribed Concrete Design Mixes

Use this table if you can accurately weigh out the cement, sand and aggregate.

For example if you can use a batching plant. This method uses the correct amount of cement to reach the design strength of the concrete.

Conclusion

Prescribed concrete mix design is far more competitive than concrete deign by volume ratio.

Trial mixes are carried out by taking samples of your aggregate and sand, to work out the correct proportions of each to maximise compaction of the cured concrete.

A concrete technician can then design a prescribed mix beginning with selecting the workability slump types. Then the concrete technician will select the correct water/cement ratio and additives for the concrete design.

The final part of the process is to make a sample of the concrete and test it at 28 days to ensure it meets the design strength.