Shotcrete Mixer Plant

Learn about shotcrete mixer plant mining engineering, tunnelling and concrete

Finance your project

Shotcrete Mixer Plant

Table of Contents

Mining Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

Unique Innovations

- Fibo Mining plant has a cement filtering option that captures 99% of the cement dust when mixing.

- Fibo Mining plant has a pump dosing option that is designed to allow the pump to pump concrete continuously.

Shotcrete Mixer Plant

Fibo Intercon manufactures several sizes of shotcrete batching plants they are:

- 1200 series 10 to 15 m3 per hour output

- 1800 series 15 to 30 m3 per hour output

- 2200 series 20 to 45 m3 per hour output

The plant can be set up with one double aggregate bin holding 4.8 m3 and 7.8 m3 with extended sides. : approximately 8 tons and 16 tons.

Or two double aggregate bins holding a total of 9.6 m3 and 15.6 m3 with extended sides. : approximately 16 tons and 26.5 tons.

Cement is dosed from a horizontal, vertical, big bag silo or a combination of two. In a mine, for example, cement may be transported in bags. A big bag silo can then be filled with cement and discharged into a horizontal or vertical silo to increase storage capacity. The big bag silo holds 3 tonnes of cement, whereas the horizontal and vertical cement silos can hold from 20 to 60 tonnes of cement.

The batching plant can be mounted on a hooked skid, frame and feet, trailer, or a wheeled bogie giving flexibility.

A state of the art software controls the shotcrete concrete batching plant. The software allows up to fifty mixes to be stored and includes the following features and benefits.

- Stock control – You don’t run out of sand, stone, cement, chemical stock.

- Torrance alerts: The quality of concrete is consistent and predictable.

- Maintenance alerts – Your plant will keep running with minor preventative maintenance up to a service.

- Management control – Simple mix set up – You can change a mix using your mobile phone, pad or laptop.

- All batch data stored – You can trace every batch of concrete produced on the plant for up to seven years.

A Fibo Intercon Mobile concrete plant doses with a standard setup to an accuracy of +- 3%, and with pre-weight cement an accuracy of +- 1%.

An alarm goes off if any tolerance goes over the settings.

Computer monitoring means that you can produce high-quality concrete following BS 8500 EN 206.

Concrete waste is one of today’s fundamental problems.

Concrete waste on-site can be 10/15%.

With Fibo concrete production, you can produce the exact amount of concrete needed, thus minimizing waste.

Fibo concrete technicians can support you with your concrete mix design and concrete testing.

We can also help you with your concrete quality processes and systems to ensure you deliver concrete to your client’s specifications.

Grout Mixing Plant

Fibo Intercon manufactures several sizes of grout mixing plants. They are

- 1200 series 10 to 15 m3 per hour output

- 1800 series 15 to 30 m3 per hour output

- 2200 series 20 to 45 m3 per hour output

The grout mixing plant is the same design as the shot mix batching plant but comes without any aggregate storage bin. The same software controls the plant, so you are in complete control.

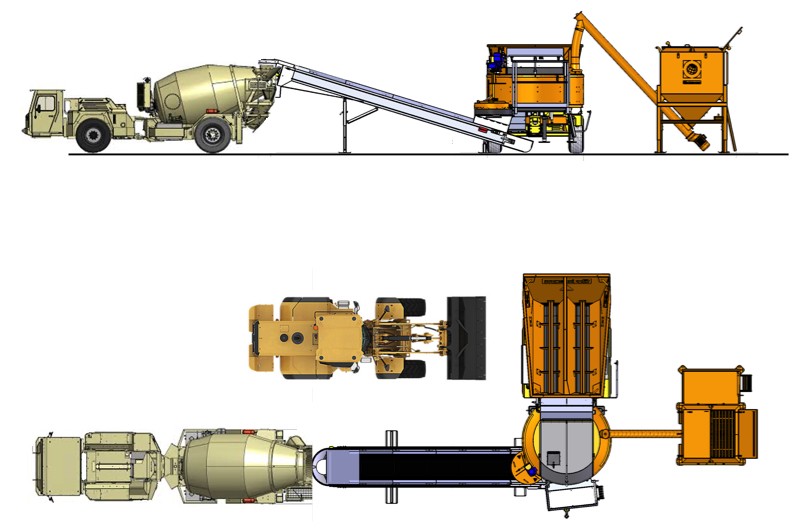

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.