Tunnel Engineering

Learn about tunnel engineering mining and concrete

Finance your project

Tunnel Engineering

What Does A Tunnelling Engineer Do?

Tunnel engineering is a branch of geotechnical engineering. Engineers are attracted to tunnel engineering as there are many problems to solve, and engineers love to solve problems.

There are lots of construction methods to build a tunnel. The type and technique depend on the tunnel’s length, the tunnel’s diameter, the geological strata and the water conditions.

Tunnel methods include:

- Tunnel boring machines (TBMs)

- Sprayed concrete-lined tunnels.

- Blasting with explosives

- Pipejacking

- Thrustboring

For example, pipejacking and thrustboring can be used in soft material, and tunnel boring and blasting is used to tunnel through medium and hard rock.

There are lots of use for a tunnel, including rail, road, mining, pedestrian transportation.

Tunel design can be challenging, especially when tunnelling through many different geological strata and tunnelling under cities where there are already many tunnels in operation.

Some of the roles that an engineer can work on in tunnelling include:

- Geotechnical engineering

- Tunnel design

- Site supervision and construction management

- Instrumentation and monitoring

- Tunnel rehabilitation

- Waterproofing and water control

- Mining support

Tunnels are constructed in urban and rural locations with many types of geology that include soft ground, hard rock and a mixture of both.

The design process for a tunnel includes:

- A feasibility study

- Conceptual design

- Final design

- Detailed cost estimates

- Risk management

- Value engineering

- Construction support

- Waterproofing design

- Mechanical tunnel ventilation

- Health and safety management

Civil engineers are pioneers in designing, constructing and maintaining everything from geotechnical engineering to turnkey tunnel construction.

Did you know

The longest tunnel runs from the town of Erstfeld and Bodio in the Swiss Alps. The tunnel is 57,000 m long and reaches a depth of 2,300 m.

The deepest mine is AngloGold Ashanti’s Mponeng gold mine in South Africa. The depth of the mine is 3,840 m.

Mining Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

The mixing plant is controlled by a state of the art software that ensures concrete quality and efficiency in delivering outstanding productivity.

Learn more about Fibo Intercon shotcrete and grout mixing plant.

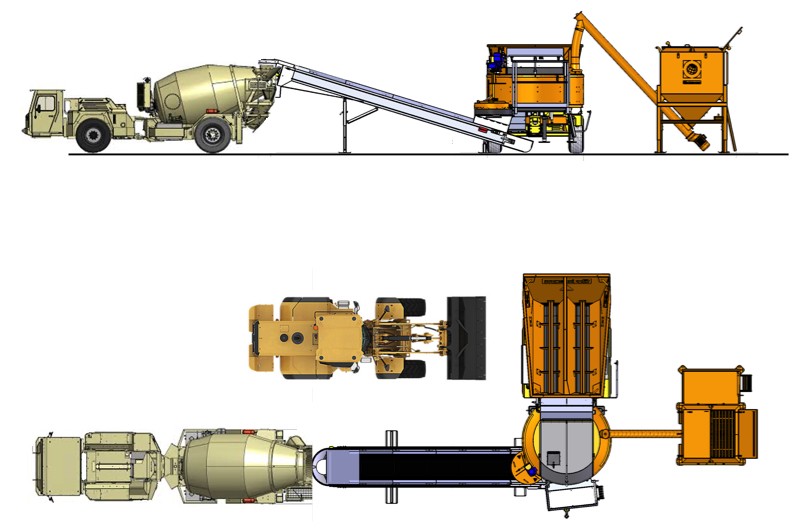

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.