Tunnel Linings

Learn about tunnel linings, mining and concrete

Finance your project

Tunnel Linings

Temporary, Primary and Permanent Tunnel Linings

Tunnel linings are the support system of a tunnel or shaft. Tunnel lining can be temporary, primary or permanent, and constructed from steel and concrete in many forms.

Temporary tunnel linings are used before the permanent lining can be put in place.

Primary tunnel linings are used to stabilize the tunnel surface before the permanent lining can be put in place.

The permanent tunnel lining is designed to carry the long-term loads of the tunnel. The design may include the primary support system.

The tunnel lining construction method will depend on the ground conditions and geological strata. There are many different types of lining, including:

- Precast concrete segments

- In-situ concrete that is cast in position

- In-situ concrete that is sprayed in position

When the ground condition is soft, the lining system must support the surrounding ground and the loads from the jacking equipment.

Cast-iron and steel segmented linings are also used in soft ground. They are durable and have high compressive strength. Cast- iron and steel segments are then finished using a sprayed concrete to infill the segments and protect them from corrosion.

Precast concrete linings are more economical than cast-iron and steel, but they can be problematic to achieve water tightness.

When tunnelling through self-supporting ground, expanding tunnel linings can be used. The tunnelling machine shield pushes forward, leaving an unsupported space. The precast concrete lining is then put into place, expanded against the tunnels exposed ground, and pushed out under pressure.

In hard ground, shotcrete is used to line the tunnel. Shotcrete is a wet mixed concrete that is sprayed onto the tunnel surface using a compressed air technique.

NATM (New Austrian Tunneling Method)

Australia has been an innovative country in the mining sector. Not only did Australia invent rock reinforcement technology, but it also developed the NATM system of tunnelling in the 1960s. The NATM process revolutionized the tunnelling industry.

The NATM process uses the inherent geological strength of the surrounding rock mass to give the tunnel stabilization. The method uses a design as you go approach and has sped up productivity and made tunnelling more economical.

The initial support system is sprayed on concrete with fibre and or welded-wire attached to the rock.

Mining Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

The mixing plant is controlled by a state of the art software that ensures concrete quality and efficiency in delivering outstanding productivity.

Learn more about Fibo Intercon shotcrete and grout mixing plant.

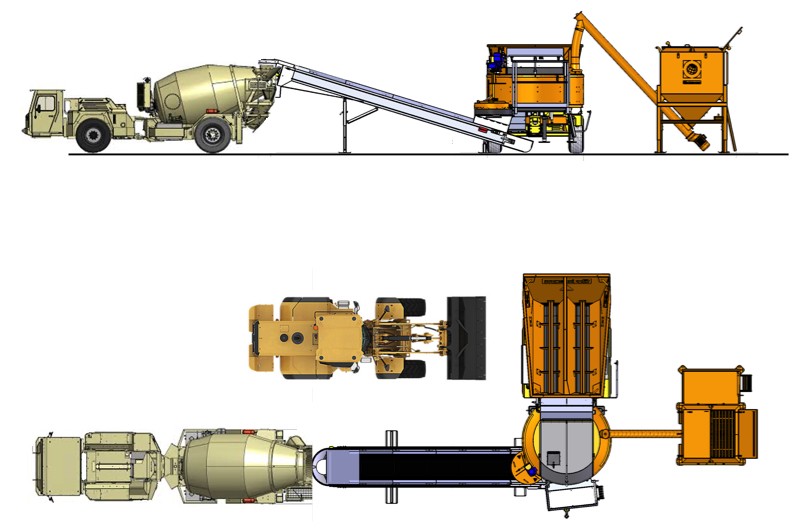

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.