Waterproof Engineering

Learn about waterproof engineering, mining engineering, tunnelling and concrete

Finance your project

Waterproof Engineering

Table of Contents

Waterproofing Mines and Tunnels

Waterproofing mines can be a challenge. Tunnels close to the surface usually are constructed using a cut and cover method and waterproofed quite easily.

Deep underground tunnels are more challenging. The water pressure at depth and the options available mean the work has to be well planned.

Most bored tunnels are below 50 metres, and at these depths are constructed through some form of rock.

Standard methods of tunnel construction include excavation using heavy plant and large tunnel using TBMs (Tunnel Boring Machines). If required, rock reinforcement is used by drilling and fixing rock anchor bolts and a sprayed shotcrete concrete lining.

Most tunnels receive a layer of shotcrete that acts as the a temporary, primary or permanent lining. Waterproof engineering takes advantage of this shotcrete lining to waterproof the tunnel.

Once the first layer of shotcrete is applied, work can begin to install a drainage system and or a waterproofing membrane.

The final part of the process is to fix steel reinforcement and cast the permanent structural lining using in-situ concrete in slip-forms or another layer of shotcrete concrete.

Every project is different and requires a design. The design process can be continuous as the tunnel passes through different types of rock and earth.

Waterproofing Methods

Four main waterproofing methods can be used. They are:

- Crystalline Systems

- Membrane Systems

- Drainage and Water Stops

- Polyurethane Grout Systems

- Crystalline Systems

Adding crystalline admixture into the shotcrete makes it waterproof and self-sealing. The admixture is added to the shotcrete mix during batching. In the past, the crystalline system was sprayed onto the surface of the shotcrete. The results are better when it is added as an admixture.

Crystalline shotcrete is used for the repair of the waterproofing lining in bored tunnels. It can be used as a slurry coat for repairs.

Membrane Systems

The membranes are made from PVC, TPO or polyethylene. They are normally applied onto a shotcrete surface applied to the rock surface to iron out sharp edges and make a smooth surface.

Once the membrane is in place, steel reinforcement is fixed, and concrete is cast as the permanent lining, typically using a slip form method of construction.

Drainage and Waterstops

Some tunnel designs allow for some water leakage as the cost to stop it is too high, especially when the water is under pressure. In these cases, a drainage system is designed to reduce the hydrostatic pressure within the rock.

The design allows the water to be drained away quickly to a drainage system. The drainage system may include drainage pipes, water stops, sumps, pumping chambers and pumps.

Polyurethane Grout Systems.

There are many intersections within tunnel construction with ventilation plant, other shafts, stop ends, construction joints and fissures.

Polyurethane grout is used and injected into the joint as a liquid resin. The resin reacts with the water and forms a permanent seal.

Mining Shotcrete and Grout Mixers

Fibo Intercon mining products are second to none. When looking for reliability, long life and quality shotcrete and grouting plant, look no further.

Fibo has several tunnel and mining shotcrete mixing layouts to suit different mine and tunnel requirements.

The mixing plant is controlled by a state of the art software that ensures concrete quality and efficiency in delivering outstanding productivity.

Learn more about Fibo Intercon shotcrete and grout mixing plant.

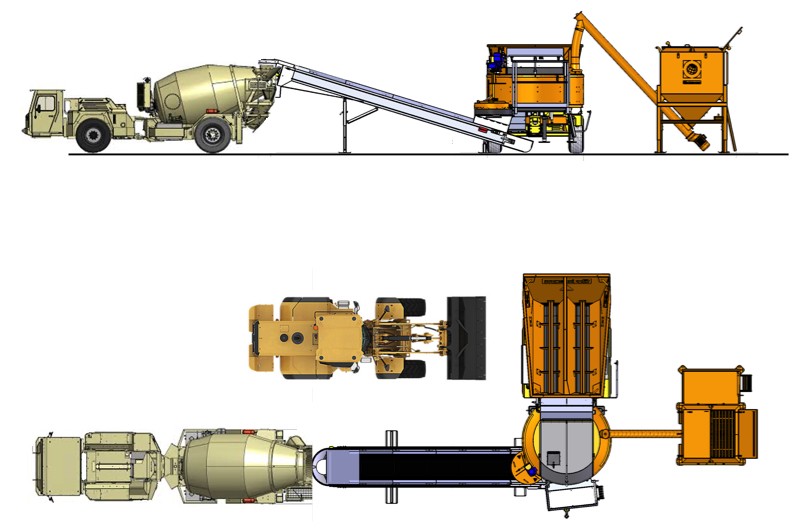

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 1

Shotcrete Batching Plant Option 2

Shotcrete Batching Plant Option 2

Take a Look at Our Mining and Tunnelling Batching Plant

We have concrete batching plant specifically designed for the mining sector. Our business has over seventy years of experience building batching plants and solving engineering problems. Take a look at the plant and get in touch. Our batching plant is very modular and we can adjust it to solve many engineering challenges.

Fibo Global

Fibo is trusted by more than 700 owners of concrete mobile batching plants all over the world because we help our customers to grow their business every day. Watch the video to see Fibo Batching plant that is going to global locations. Jesper gives you a look around the factory production area in a virtual site visit to the factory.

Complete the form and we will make contact with you to discus your requirements or to answer any questions you may have. Alternatively chat to use using the WhatsApp chat on the page.